Высокоточная инструментальная измерительная машина MXP

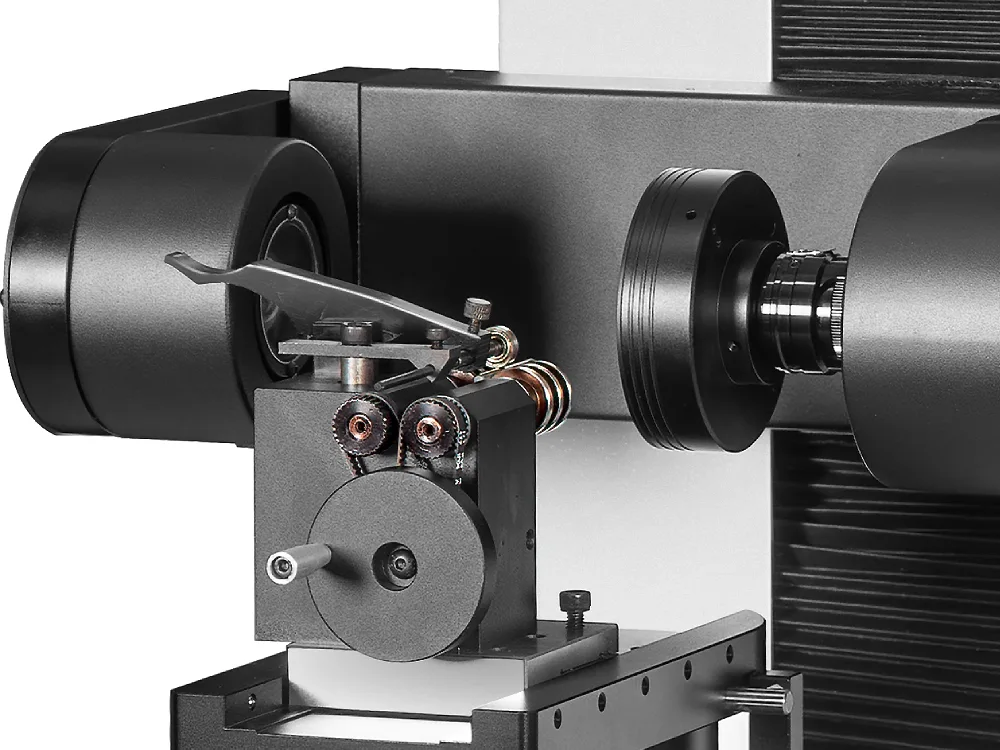

Оборудование эргономично, компактно и надежно. Оно оснащено высокоточной V-образной инструментальной оснасткой и поворотным столом для проведения измерений под разными углами.

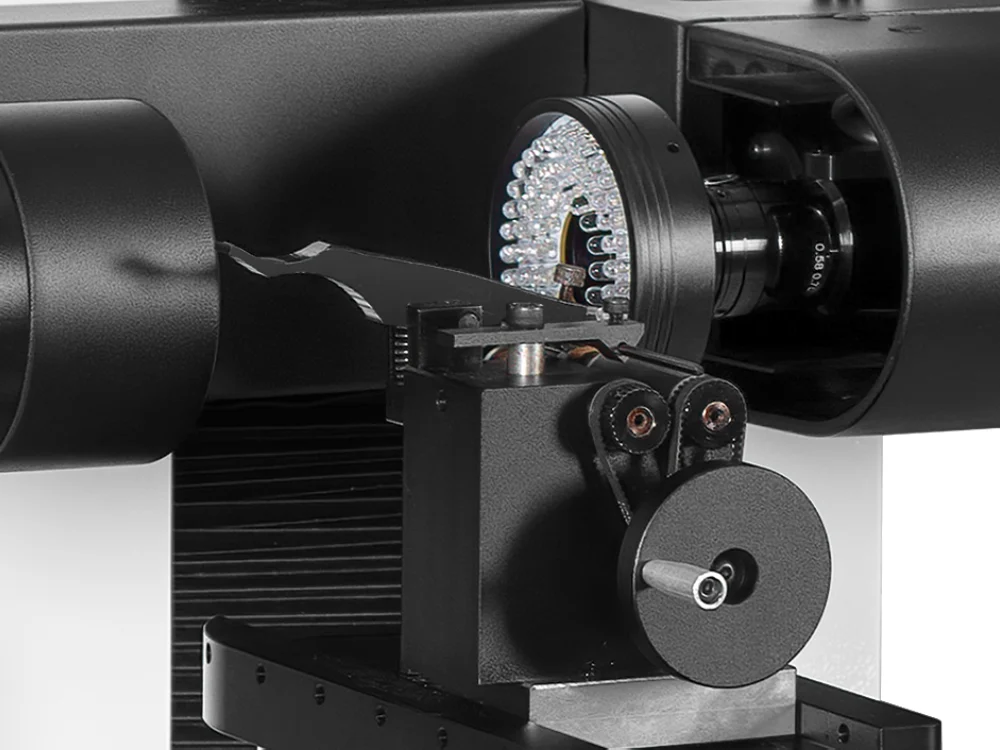

Благодаря функции захвата и отображения изображений высокой четкости, пользователи могут выбирать суперувеличение на уровне микроскопа, а также оснащены измерительным программным обеспечением SMARTOOL.

Стандартный 8-зонный светодиодный кольцевой источник света с плавным управлением поддерживает автоматический поиск кромок, быстрое измерение углов и сравнение графиков CAD. Результаты измерений можно вывести в виде отчета Excel или файла CAD.