Координатно-измерительные машины это устройства, выполняющие геометрический анализ. Производители используют КИМ для трехмерных измерений, определения допусков и контроля качества. На протяжении более 50 лет КИМ являются неотъемлемой частью нескольких важнейших отраслей промышленности. Причина этого довольно проста. Заводы стремятся исключить человеческий фактор из своих процессов. Обычные метрологические инструменты, такие как штангенциркули, высотомеры и микрометры, очень подвержены этому. КИМ же позволяют снизить вероятность личных ошибок в производственном процессе. Они экономят деньги, время и сырье.

Что такое машина КИМ?

Основная цель CMM это измерение деталей. Оно выполняется с помощью физической или оптической измерительной системы. КИМ состоит из зоны контроля, корпуса, опорной балки, контактного датчика, щупа и компьютера. Щуп установлен на рычаге датчика. Он способен совершать ортогональные движения в трех направлениях в декартовой плоскости. Различные методы для каждой КИМ обеспечивают это движение. На кончике щупа находится сенсорный триггер. Триггер фиксирует координаты каждой точки на корпусе детали и отправляет эту информацию на компьютер. Компьютер генерирует 3D-модель CAD, используя это "облако точек". КИМ позволяют выполнять высокоточные 3D-измерения.

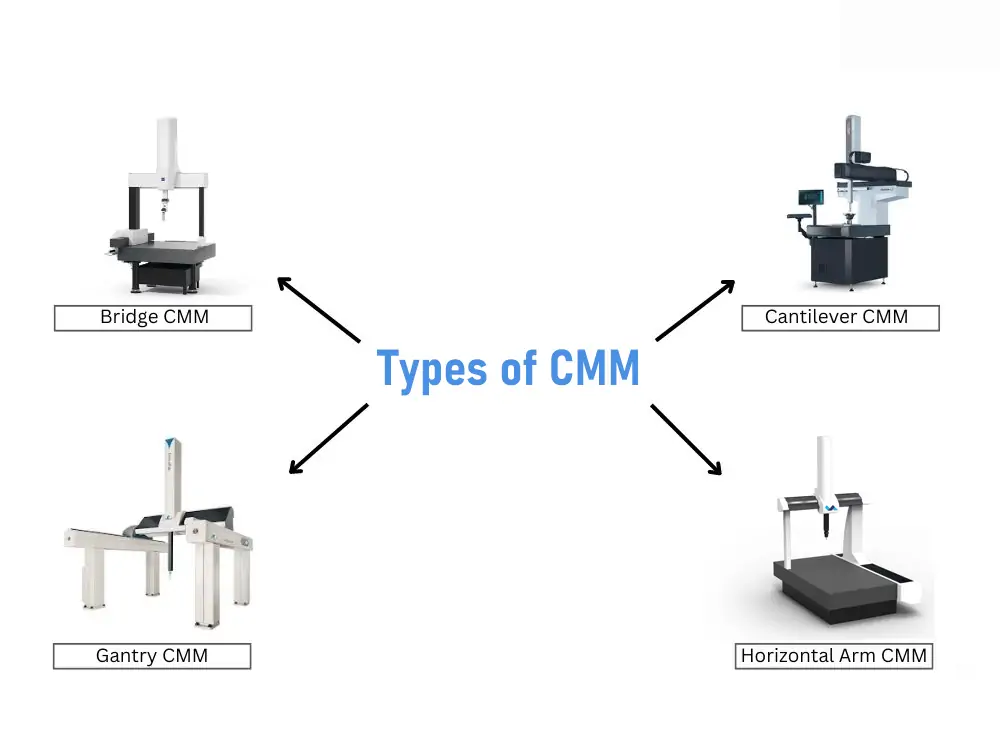

Различные типы КИМ

Мост КИМ

КИМ Bridge - одна из наиболее широко используемых КИМ в промышленности. Она отлично подходит для измерения деталей малого и среднего размера. Он состоит из двух опорных стоек и поперечной балки. К поперечной балке крепится измерительный рычаг, обеспечивающий вертикальное перемещение. Подвижная рама и рычаги обеспечивают две другие оси измерения.

Плюсы

КИМ Bridge не только универсальна, но и обладает высокой точностью. Это идеальный выбор для обработки деталей с высокими допусками. Она выпускается в двух вариантах: с подвижным и неподвижным мостом. Они подходят для нескольких типов мастерских. Мостовые КИМ могут выполнять различные задачи, такие как измерение, профилирование и сканирование.

Cons

Стоимость является одним из ограничивающих факторов для КИМ мостового типа - они, как правило, дорогие. Кроме того, их объем ограничен конструкцией. Рабочим приходится переносить детали в зону контроля, что не всегда идеально. Наконец, для работы с ними требуются квалифицированные операторы, и они чувствительны к внешним воздействиям.

Портальная КИМ

Портальная КИМ имеет поперечную балку, опирающуюся на две параллельные рамы с каждой стороны. Поперечная балка свободно перемещается вверх и вниз по балке. Рука датчика, прикрепленная к поперечной балке, также перемещается в стороны. Наконец, как и в КИМ мостового типа, датчик перемещается по вертикали для получения конечной координаты перемещения. Портальные КИМ предназначены для анализа крупных деталей машин и часто устанавливаются непосредственно в цеху.

Плюсы

Портальные КИМ - это высокоточные и надежные варианты для измерения деталей автомобилей. Благодаря большому объему штатива в них можно разместить большинство деталей среднего и большого размера. Поскольку портальные КИМ устанавливаются на полу, их легче загружать и разгружать с более тяжелых деталей машины.

Cons

Как и мостовые КИМ, портальные КИМ также достаточно дороги. Однако, поскольку это специализированный тип КИМ, они стоят инвестиций. Если вы вложите в них деньги, имейте в виду, что они огромны. Портальные КИМ занимают много места в цеху. В конечном итоге, поскольку это КИМ фиксированного типа, их общий объем ограничен.

КИМ с горизонтальным рычагом

Некоторые детали, такие как автомобильные панели и пластины, преимущественно одномерны. Они могут быть короткими, но иметь значительную длину. Такие нестандартные детали не могут быть удобно измерены мостовыми или портальными КИМ. КИМ с горизонтальным манипулятором состоят из бокового измерительного рычага. Вместо вертикального перемещения он движется горизонтально. Таким образом, он может легко измерять объекты с длинными профилями. КИМ с пластинами и КИМ с подиумами - два типа устройств этой категории.

Плюсы

КИМ с горизонтальным рычагом могут измерять объекты с длинными профилями. Они просты в установке и эксплуатации и отлично подходят для деталей, требующих меньших допусков. Кроме того, они занимают мало места и экономичны.

Cons

Они обеспечивают меньшую точность, чем другие типы КИМ. Из-за горизонтальной конструкции они ограничены преимущественно одним измерением. Несмотря на компактность, они все равно требуют подносить к ним деталь, поэтому не обладают преимуществом портативности.

Консольная КИМ

Когда компания Ferranti впервые разработала КИМ в Шотландии в 1970-х годах, она выпустила КИМ консольного типа. Эта КИМ имеет жесткое основание, к которому прикреплена горизонтальная балка. Балка содержит измерительный рычаг и щуп. Она отличается от КИМ мостового типа тем, что имеет только одну раму. Она обеспечивает открытый доступ с трех сторон машины. Консольная КИМ обеспечивает высокую точность и подходит для малых и средних объектов.

Плюсы

Консольные КИМ обладают высокой точностью и низкой вероятностью ошибок измерения. Они особенно эффективны при измерении небольших деталей, таких как электронные компоненты. Поскольку они открыты с трех сторон, оператор может удобно загружать и выгружать детали. Консольные КИМ отличаются высокой скоростью измерений. Они подходят для мастерских, где требуется быстрая производительность.

Cons

Из-за жесткой конструкции балки с осью X консольные КИМ ограничены в размерах объектов, которые они могут измерять. Кроме того, они не являются портативными. Они должны быть установлены на станции в цеху, а оператор должен приносить детали для измерения.

Портативная измерительная рука КИМ

КИМ с переносной рукой отлично подходят для измерений на месте, они изменили работу КИМ в цехах. Они состоят из шарнирного рычажного датчика с наконечником в виде щупа. КИМ можно перемещать на различные участки цеха для измерения деталей. Портативные измерительные манипуляторы оснащаются системами с шестью-семью осями, что позволяет с легкостью профилировать сложные детали. Они могут анализировать объекты на разных стадиях сборки, от отдельных деталей до целых машин.

Плюсы

Самая легкая и маневренная из КИМ, портативная измерительная рука может изменить подход к размерному анализу в цехе. Они оснащены технологиями Leapfrog, мультисенсорными и сканирующими технологиями. Портативные манипуляторы недороги и просты в эксплуатации.

Cons

Из-за своей портативности эти типы КИМ имеют ряд недостатков. Они не такие точные и прецизионные, как КИМ мостового типа, а значит, не подходят для высокочувствительного оборудования или оборудования с мелкими деталями.

Оптическая КИМ

Достижения в области машинного зрения позволили оптическим КИМ стать передовым методом измерения. Оптические КИМ не используют физические датчики, а применяют оптические методики для измерения объектов. Они выполняют анализ размеров с помощью лазерной триангуляции, фотограмметрии и систем визуализации. Это делает оптические КИМ идеальными для измерения хрупких и деформируемых деталей. Оптические КИМ позволяют проводить поточный контроль объектов во время сборки. Они незаменимы для производства и автоматизации, составляя основу Индустрии 4.0.

Плюсы

Оптические КИМ, как и КИМ с измерительной рукой, мобильны и легки. Они отличаются быстрым временем сбора данных. Они универсальны в работе, легко выполняют сканирование, зондирование и профилирование. Они дешевы в приобретении и просты в настройке. Простые в эксплуатации, они подходят для большого числа случаев использования. Оптические КИМ - лучший способ измерения небольших и деформируемых деталей машин.

Cons

Оптические КИМ менее точны, чем обычные КИМ, такие как мостовые или портальные. Для их оптимальной работы требуется специальное освещение. Кроме того, оптические КИМ иногда испытывают трудности при измерении блестящих и отражающих поверхностей. Кроме того, оптические КИМ могут неточно измерять прозрачные материалы.

Выбор правильной КИМ для ваших нужд

КИМ стали ведущим решением в области измерений, позволяющим сократить количество ошибок, совершаемых человеком в процессе производства. Улучшая контроль качества и измерения размеров, КИМ повышают эффективность производственного процесса. Со временем это приводит к снижению расхода сырья, экономии на операциях и увеличению объемов производства.

При выборе КИМ учитывайте специфику применения. Хотя консольные КИМ очень точны, они не очень универсальны. Наиболее гибкими в использовании являются КИМ мостового и портального типов.

КИМ с горизонтальной рукой подходит для измерения длинных объектов. Портативные измерительные руки и оптические КИМ лучше всего подходят для переносных и модульных операций. Если у вас есть дополнительные вопросы по выбору КИМ, свяжитесь с нами. Мы будем рады услышать о ваших потребностях в измерениях.