Традиционные измерительные инструменты, такие как штангенциркули и оптические компараторы, хорошо работают в лабораториях. Однако промышленное производство предъявляет жесткие требования. Обычные инструменты здесь не работают. Именно тогда вам понадобится измерительная система технического зрения. Измерительные системы технического зрения - это устройства обработки изображений. Они повышают скорость и эффективность измерения размеров. Они обладают множеством функций, оптимизирующих конвейерное производство.

В этой статье мы расскажем о важности систем измерения с помощью зрения и о том, как они в значительной степени заменили традиционную метрологию.

Принцип работы

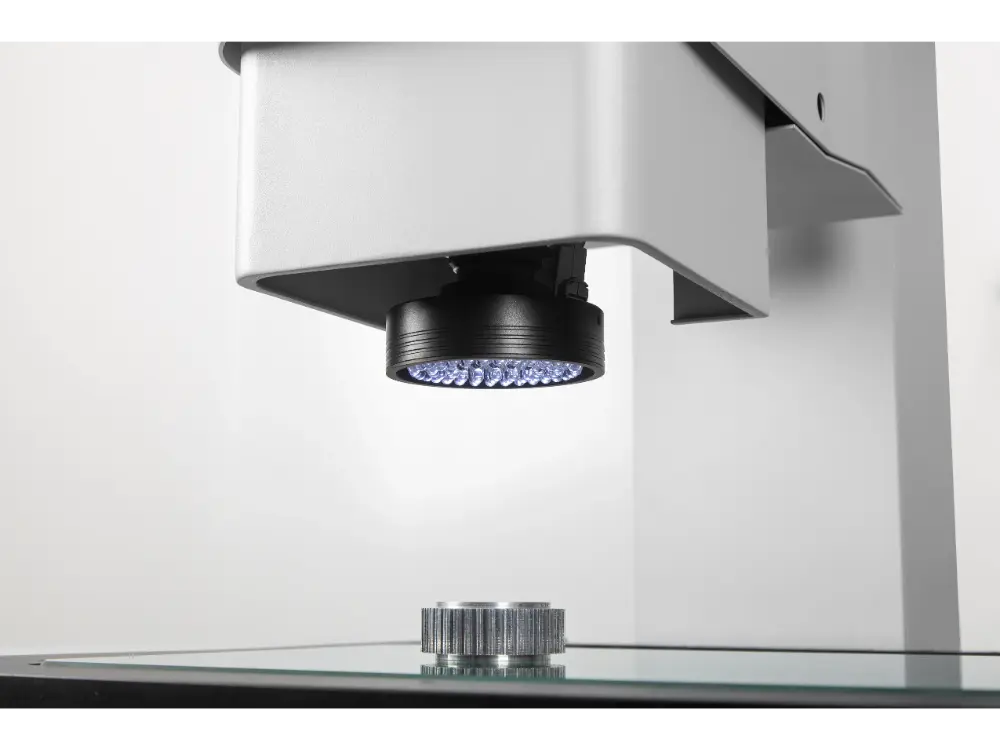

Для понимания систем измерения технического зрения лучше всего разделить их на три части. В целом, каждая часть проста для понимания. У вас есть оптическая линза, камера и программное обеспечение для обработки изображений. Последняя часть делает систему измерения зрения тем, чем она является.

Для работы системы измерения зрения необходимо окружающее освещение. Камера делает снимок объекта. Затем компьютерное программное обеспечение обрабатывает изображение в 2D или 3D. Считая пиксели, мы измеряем расстояние на изображении. Чем выше разрешение, тем больше количество пикселей, а значит, и точность. 2D-видение стало возможным благодаря таким технологиям, как автоматическое определение краев и субпиксельная обработка. Системы 3D-видения также используют передовые фотограмметрические технологии, такие как лазерная триангуляция или структурированный свет. Посмотрите Высокоточная измерительная машина MXP.

Основная важность размерных измерений

Независимо от того, что вы производите, измерение размеров - важнейшая производственная задача. Оно необходимо независимо от того, работаете ли вы с пластиком, металлом или деревом. Оно одинаково важно для готовых изделий, OEM-производителей или деталей машин. Неудивительно, что измерение размеров лежит в основе всех задач контроля. Если традиционная метрология обеспечивала рудиментарные средства контроля, то визуальные инструменты полностью изменили ее. Системы визуальных измерений не зависят от физического контакта. Они работают на быстро движущихся сборочных линиях. Уменьшая помехи, они ускоряют традиционные процессы, такие как проверка "прошел-не прошел". Машинное зрение может помочь вам, если на вашей сборочной линии одновременно перемещается огромное количество продукции. Инструменты машинного зрения могут сканировать множество объектов одновременно. Таким образом, они выявляют аномальные продукты или производственные дефекты.

Как для малых, так и для крупных производителей обнаружение неисправностей и контроль продукции являются важнейшими процессами. Вы, скорее всего, сэкономите на сотрудниках, потому что инструменты визуального контроля могут выполнять проверку на допуск гораздо более надежным и эффективным способом. Они выполняют это распознавание без физического контакта с объектом. Как это поможет вам в долгосрочной перспективе? В случае повторяющихся неисправностей проблема может заключаться в конструкции оборудования или изделия. Системы машинного зрения помогают выявить причину. Со временем это позволяет оптимизировать производственный процесс, запустить механизмы самокоррекции и ускорить выпуск продукции.

Приложения

Системы визуального измерения могут выполнять задачи, которые требуют огромных человеческих затрат. Таким образом, они экономят затраты и делают задачи, которые раньше считались невозможными!

Размерный анализ электронных компонентов

Оценка допусков небольших электронных компонентов, таких как диоды и конденсаторы, находится за пределами человеческих возможностей. Использование традиционной метрологии затруднительно и требует много времени. Визуальный контроль позволяет проводить высокочувствительные измерения. Распространенная стратегия визуальных систем заключается в следующем. Они делят корпус конденсатора на сегменты и выполняют обнаружение краев. Кроме того, визуальные измерительные системы могут одновременно сканировать множество электронных компонентов. Без машинного зрения эти задачи потребовали бы огромных затрат времени и денег.

Измерение горлышек и крышек бутылок

Измерительные системы Vision могут выполнять контроль продукции в потоке. Они могут обрабатывать движущиеся компоненты на сборочной линии, не прерывая ее. Например, они могут обрабатывать горлышки бутылок, чтобы определить любой производственный дефект. При обнаружении отклонений измерительные системы технического зрения выполняют быструю проверку "прошел/не прошел". Измерение размеров на линии обеспечивает согласованность работы в крупном масштабе.

Проектирование печатных плат и проверка качества

Измерение микроскопических величин на печатных платах далеко не всегда под силу человеку. Без машинного зрения полагаться на людей утомительно и долго. Инструменты визуального контроля играют здесь жизненно важную роль. В микросхемах, припаянных к печатной плате, иногда могут появляться трещины, которые трудно заметить человеческим глазом. Ориентация выводов ИС, компланарность и угловатость - все это очень трудно уловить человеку. Однако для визуальных машин это проще простого. Именно поэтому электронная промышленность стала лидером по их внедрению во всем мире.

Идентификация этикеток и сканирование штрих-кодов

На пищевых предприятиях этикетки определяют решения. Машинное зрение позволяет огромным сборочным линиям работать без перебоев. Идентификация этикеток и сканирование штрихкодов играют в этом значительную роль. Данные на этикетках определяют многие критически важные действия, такие как дата окончания производства, завод-изготовитель, источник сырья и т. д.

Обработка и хранение данных

Системы визуальных измерений обрабатывают большие объемы данных. Широко распространены данные о размерах, качестве и геометрических допусках. Заводские базы данных хранят эти данные для дальнейшего использования. Данные, собранные инструментами визуального контроля, очень полезны. Как данные могут помочь мне, спросите вы? Машинное зрение делает возможным хранение данных, что, в свою очередь, облегчает их анализ. При правильном исследовании вы сможете усовершенствовать свой процесс и предсказать потребительский спрос! Это одно из самых больших преимуществ машинного зрения, которое человек не может воссоздать.

Заключение

Машинное зрение произвело революцию в работе заводов. Каждое измерение служит точкой данных, которая способствует принятию будущих решений. Производственный сектор является одним из крупнейших производителей исходных данных. Это имеет решающее значение для совершенствования и развития производственных методов. С быстрым развитием искусственного интеллекта производство переходит на новую волну автоматизации. Визуальные измерительные системы будут играть центральную роль в этой революции.