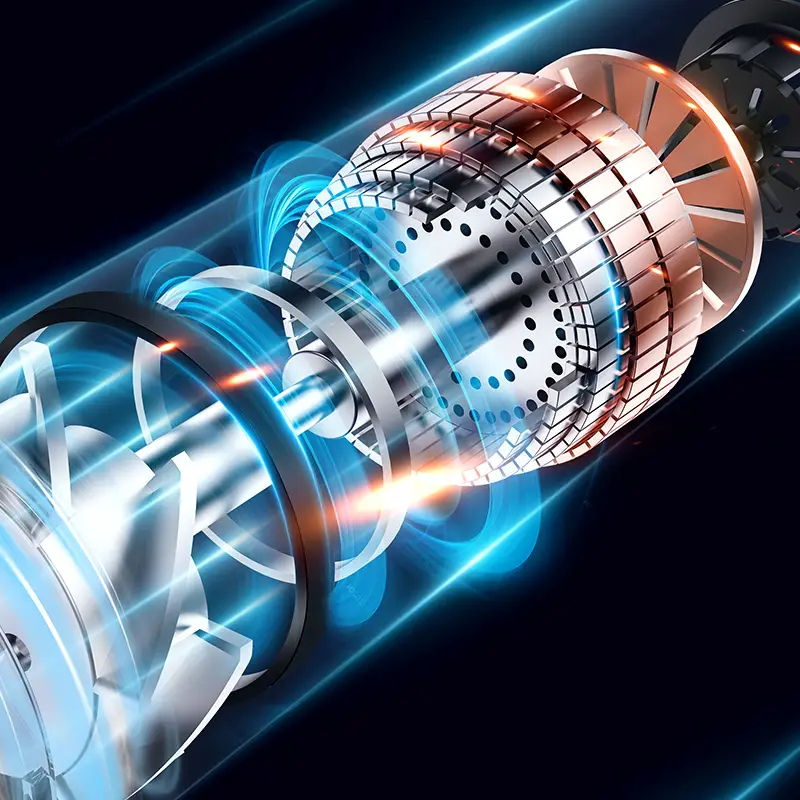

Aerospace

Vision measuring machines are vital in the aerospace industry for complex components. They must meet high-demand manufacturing needs. MXP’s high-precision cameras and software achieve micron or even nanometer-level accuracy.

Home >> Industries >> Aerospace