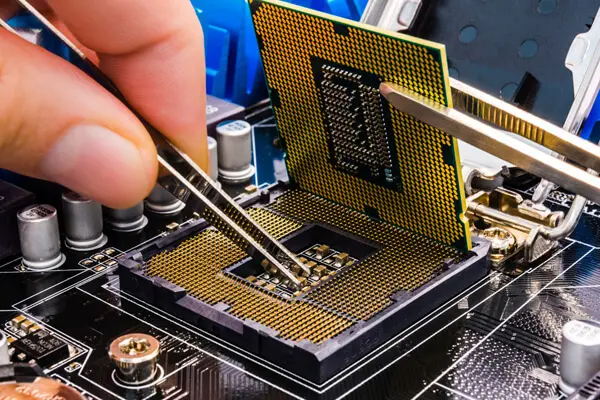

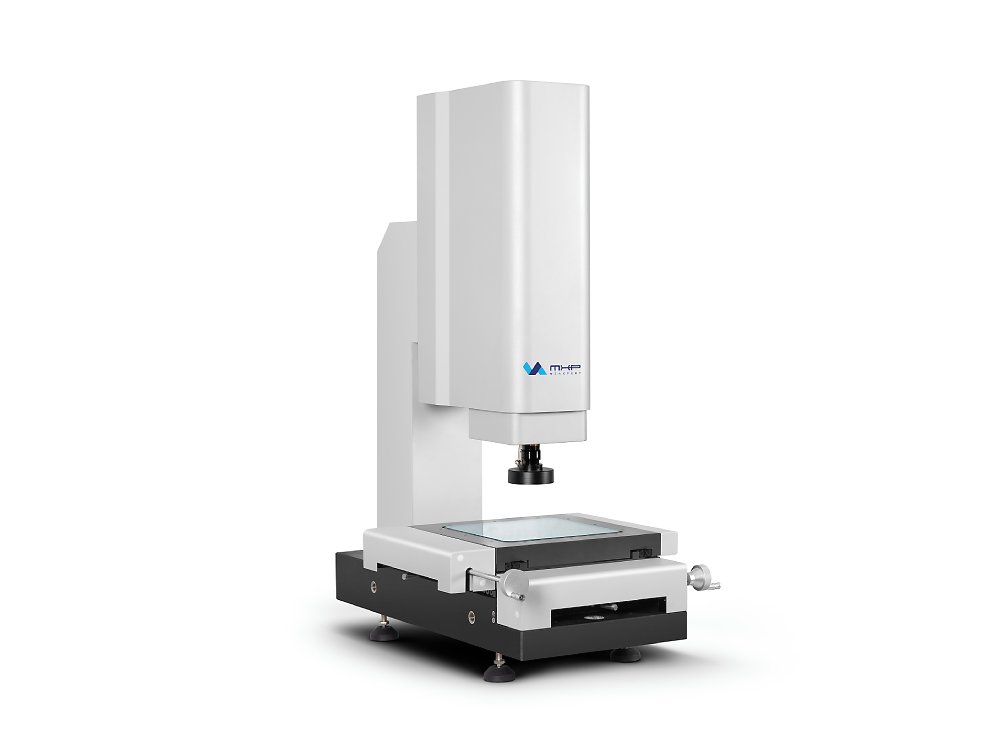

Precision Manufacturing Needs

Electronic products are constantly developing in the direction of miniaturization and high precision, requiring more powerful functions in a smaller space. Precision components such as chips and PCBs are no longer suitable for traditional contact measurement due to their fragility and sensitivity. The visual measurement system can achieve non-contact high-precision detection, while protecting the integrity of the components, ensuring measurement accuracy and efficiency, and providing real-time and accurate detection data, timely discovering production defects, and reducing the defective rate.

Technological Innovation Needs

The electronics industry is innovating at a fast pace and products are frequently updated. Traditional manual inspection can no longer meet the needs of modern production, and automated and intelligent production has become an inevitable trend. The visual measurement system meets the inspection needs of new products and processes. Its high-speed, stable, automatic inspection capability solves the inefficiency and high error rates of manual inspection.