PARAMETERS

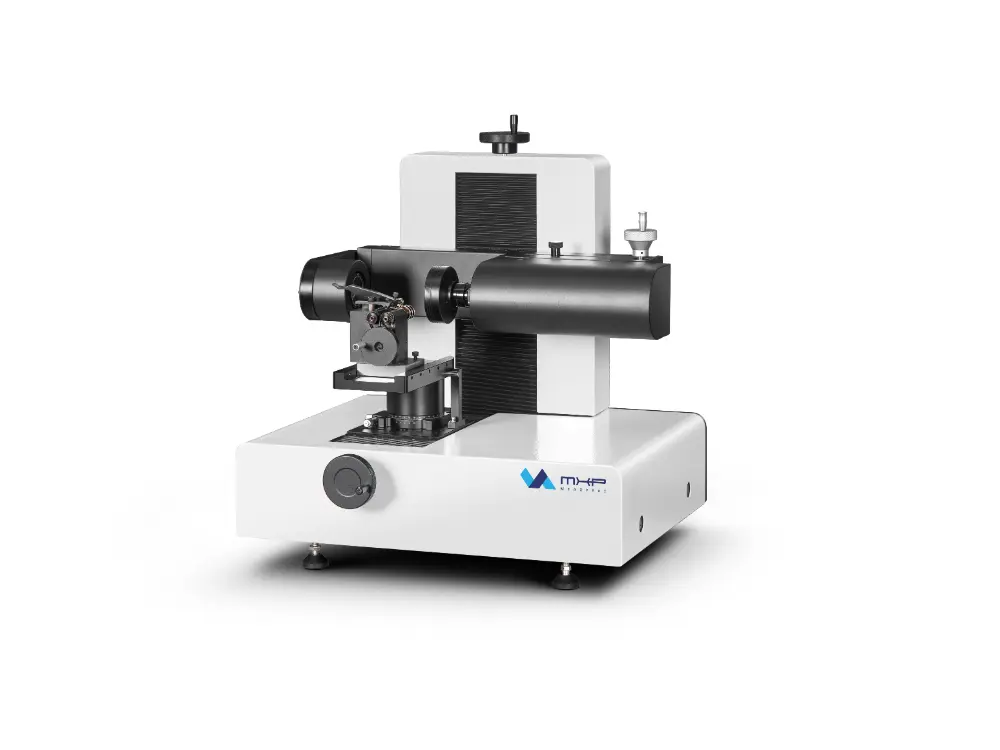

| Item | Jupiter 600 | |

|---|---|---|

| X/Y axis travel | 80/60 | |

| Z axis me asuring range | 60 | |

| Rotation angle | 0-90* | |

| Max tool diameter | 2~16mm | |

| Max tool length | 0~150mm | |

| Working distance | 80mm | |

| Lens | Electronic feedback signal zoomlens | |

| CCD | 5M pixel digital camera | |

| Linear scale resolution | 0.1μm | |

| Magnification | 12.6X79.2X/25.2X-140X (optional) | |

| Field of view | 27*20mm ~ 43*33mm/13.5*10mm ~ 2.3*1.6mm (optional) | |

| Measuring accuracy | X~Y(2.5+L/100) μm,L is the measured length | |

| PC | ALL-IN-ONE PC system, Windows 10 0S, with 24″LCD monitor | |

| Illumination | 8 section LED ring light, contour light and flexible auxiliary light, all software control and programmable. |

|

| Input format | DXF files | |

| Output format | EXCEL.DXF | |

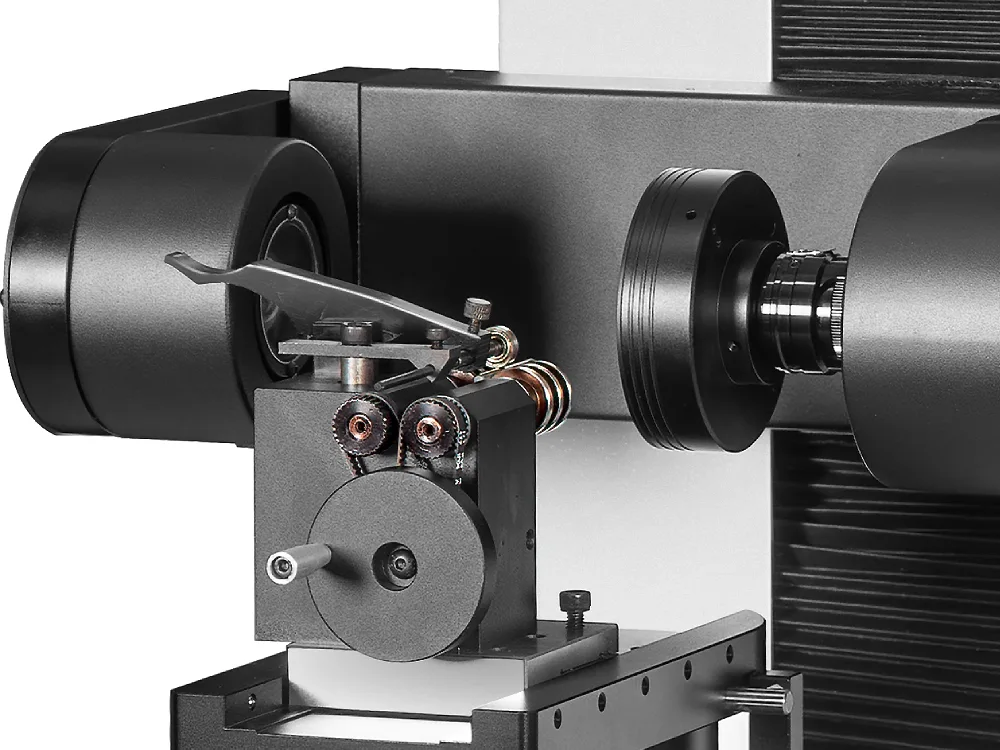

Advantages of MXP’s Tool Measuring Machine

Ergonomic design and solid construction. ALL-IN-ONE PC system makes the machine more stable.

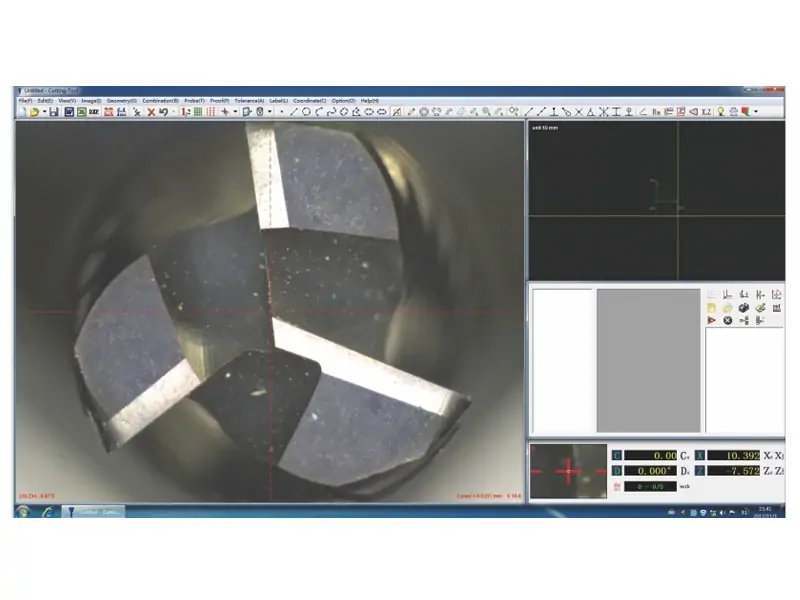

HD image capturing and display combination, and microscope magnification level is optional.

Stable and accurate V block for easy tool holding and alignment.

Mechanical fixed measuring angles of 0 degrees and 90 degrees are available on the rotary stage.

A high-accuracy encoder is embedded in the rotary table, offering precise angle location for users.

SMARTOOL measuring software offers a specific measuring function for cutting tools.

Automatic edge detection, fast angle measurement with reticle, and CAD element comparison functions are available.

Measuring results of the fast output to EXCEL file report or CAD file.

Product Features

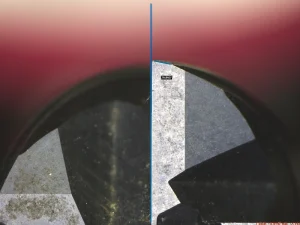

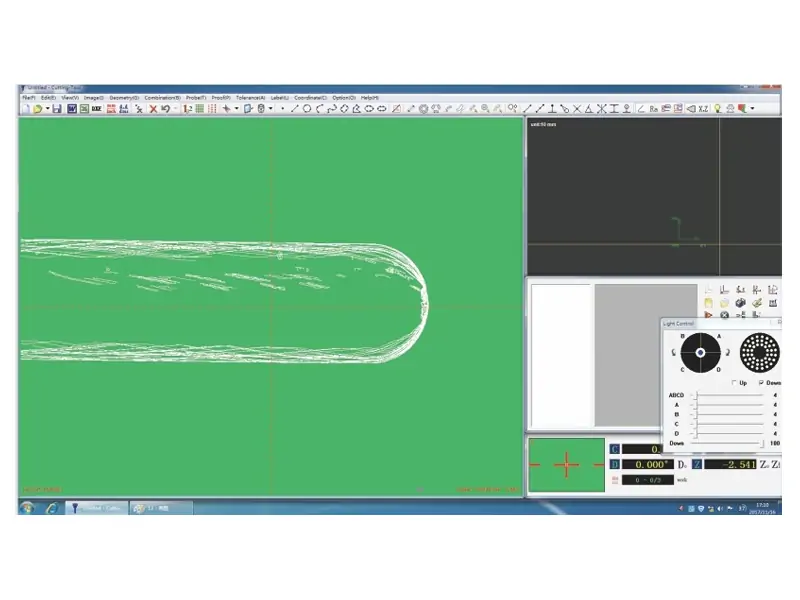

Contour Light Module

A parallel light path contour LED light module offers the user the best image and sharp edge of the object view.

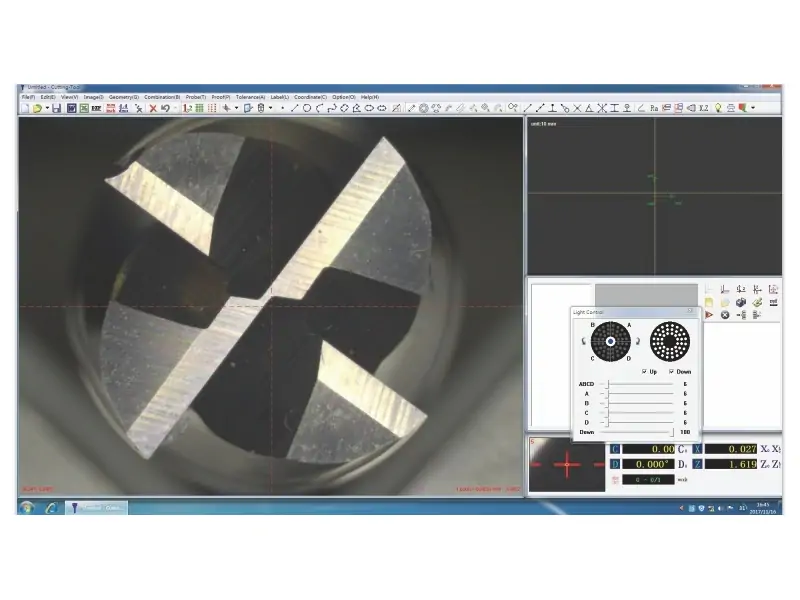

Software

The software window displays a high-resolution image and a graphical operation interface. All function keys and control panels are displayed.

Tool Holder

A multiple-section tools holder is embedded at the side of the machine. To avoid confusion, users can hold all the tools for preparation.

Light Source

It can be connected to an eight-zone upperlight source, lifting light,four-color light, and anti-collision light.

Tool Measuring System Functions

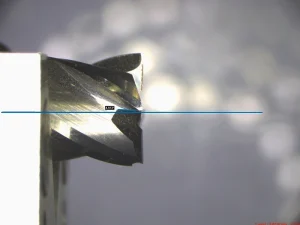

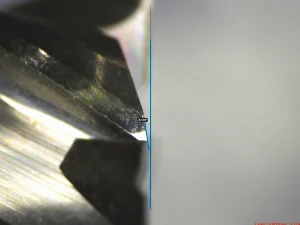

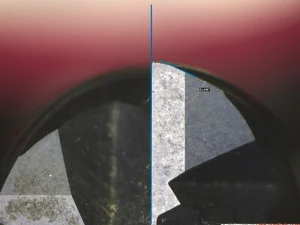

Dynamic Real-time Curve View

The software offers a real-time edge-detecting curve view, making the edge analysis and measuring more intuitive and clear. Users can switch to the curve view mode at any time during the measuring process.

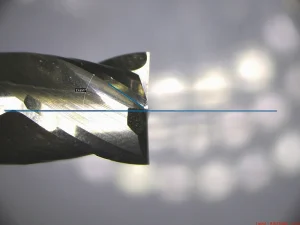

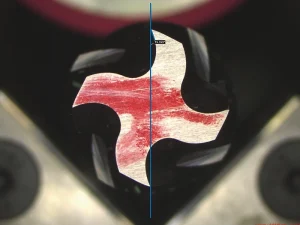

Fast Angle Measuring with Reticle

The reticle displayed in the image area of the SMARTOOL software is freely rotatable and able to display angles. Users can achieve fast angle measuring easily by using the reticle for edge comparison.

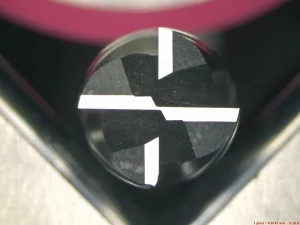

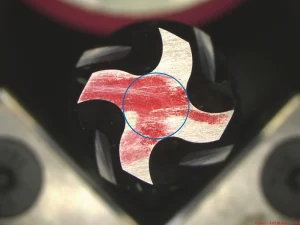

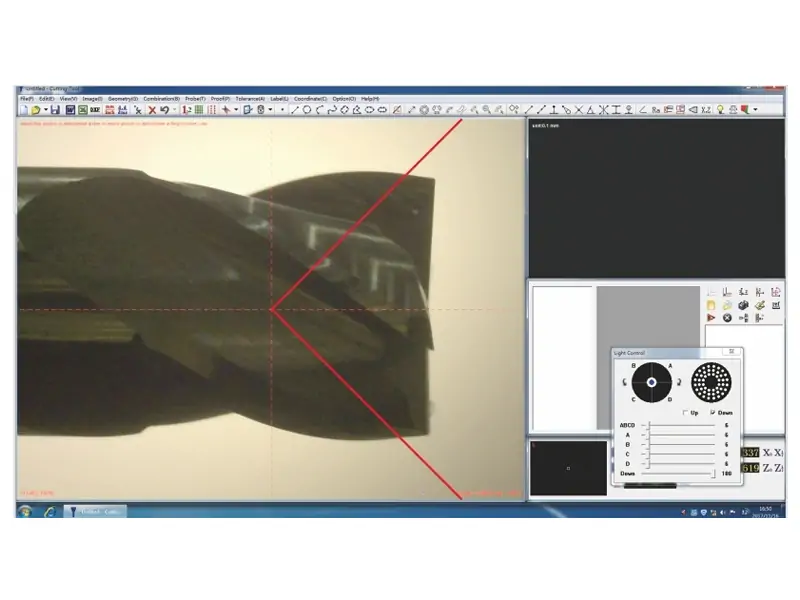

CAD Comparison

The SMARTOOL measuring software supports the CAD comparison function. Users can directly input the CAD drawing of the tool to the software as a reference, and compare the real image to the drawing to evaluate the geometries of the cutting tools.

Measuring Capability of MXP’s Tool Measuring System

SOFTWARE

Both software and hardware are even more powerful, with External-Array RationalVue composite measurement software, providing powerful 2D/3D composite measurement functions

ACCESSORIES

Programmable LED Light

HD CCD Camera

Linear scale with high resolution

Auto zoom lens